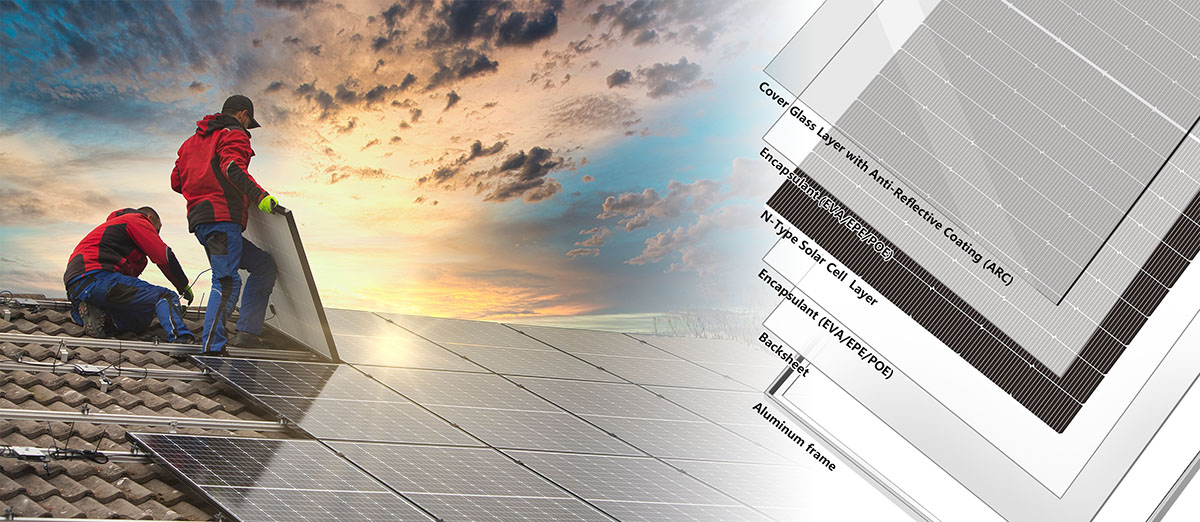

Composition structure of solar panels

With the rapid development of the solar energy industry, the solar panel manufacturing industry is also developing rapidly. Among them, the production of solar panels involves a variety of materials, and different types of solar panels may also be composed of different materials.

1.What are solar panels composed of?

Solar panels are usually mainly composed of silicon wafers, back sheet , glass, EVA, and aluminum frames:

· Silicon wafers: the core components of solar panels

As the core components of solar panels, silicon wafers also play a vital role in solar modules, and there are many types according to different structures.

The role of silicon wafers

Photoelectric conversion: Silicon wafers can convert sunlight into electrical energy, which is the core function of solar panels.

Semiconductor properties: Silicon is a semiconductor material that can adjust its conductivity by doping (that is, adding a small amount of other elements to silicon) to form a PN junction and realize the collection and transmission of photocurrent.

Types of silicon wafers

Monocrystalline silicon wafers: Made of silicon with a single crystal structure, it has high efficiency and stability, but the cost is high.

Polycrystalline silicon wafers: Made of silicon with multiple crystal structures, it has a lower cost, but its efficiency and stability are slightly inferior to monocrystalline silicon wafers.

Thin-film silicon wafers: use less silicon material, are light and low-cost, but have lower efficiency.

Ocean solar has always selected the best quality solar silicon wafers for customers to ensure that each cell is of Grade A indicator. Ocean solar's cell power requirements are also much higher than similar products.

· Backsheet: The main component of solar panels

Protection: The backsheet protects the internal components of solar panels (such as silicon wafers, cells and wires) from environmental factors (such as moisture, dust, ultraviolet rays, etc.), extending the service life of the components.

Electrical insulation: The backsheet provides electrical insulation to prevent the cells from contacting the external environment and causing electrical leakage or short circuit.

Mechanical support: The backsheet provides structural support for the entire solar panel, maintaining the overall strength and stability of the component.

Thermal management: The backsheet helps to dissipate heat, reduce the temperature of the solar panel, and improve the efficiency and performance of the cell.

Ocean solar not only has high-quality backsheets, but also expands in variety, providing conventional white whiteboards, all-black backsheets, and transparent backsheets.

· Glass: Performance and Durability of Solar Panels

Protection: The main function of solar glass is to protect the solar cells from environmental factors such as rain, snow, wind and debris. It ensures the durability and life of the solar panel.

Transparency: Solar glass is designed to be highly transparent to allow maximum sunlight to pass through the solar cells. The more light that reaches the cells, the more electricity they can generate.

Anti-reflective coating: Many types of solar glass come with anti-reflective coatings, which reduce the amount of light reflected from the surface, thereby increasing the amount of light absorbed by the solar cells.

Tempered: The glass used in solar panels is often tempered to make it stronger and more impact-resistant. Tempered glass is also more resistant to thermal stress, which is important because panels are exposed to different temperatures.

Self-cleaning properties: Some advanced solar glass options include a hydrophobic layer that helps keep the surface clean by repelling water and dirt, which would otherwise reduce the efficiency of the panel.

Ocean solar strictly selects high-strength tempered glass with high light transmittance to ensure the premium performance and ultra-long quality assurance of each solar panel product.

· EVA: Provides adhesion and light transmittance to solar panels

Encapsulation: EVA is used as an encapsulation material to protect photovoltaic cells. It is usually placed between the glass and solar cells on the top, and between the cells and backsheet on the bottom.

Protection: EVA protects against mechanical stress, environmental conditions (such as moisture and UV radiation), and potential physical damage. It helps maintain the structural integrity of the solar panel.

Optical properties: EVA has good transparency, which maximizes the transmission of light to the solar cells. This is essential to maintain high efficiency in converting sunlight into electricity.

Adhesion: EVA acts as an adhesive layer, bonding the different components of the solar panel together. During the lamination process, the EVA melts and firmly bonds the layers, ensuring stability and durability.

Thermal stability: EVA is designed to withstand the temperature changes that solar panels are subjected to during their service life. It remains stable and effective over a wide temperature range.

· Aluminum frame: Provides protection and installation support for solar panels

Structural support: Aluminum frames provide structural integrity to solar panels, helping to firmly hold the layers (such as glass, EVA, solar cells and backsheet) together.

Mounting: The frame makes it easy to mount solar panels to various structures, such as rooftops or ground-mounted systems. It usually includes pre-drilled holes or slots for mounting hardware.

Protection: Aluminum frames help protect the edges of solar panels from mechanical damage, such as impact or bending. It also provides additional rigidity, reducing the risk of damage during handling and transportation.

Durability: Aluminum is lightweight, strong and corrosion-resistant, making it an ideal material for outdoor applications. The frame helps ensure that solar panels can withstand harsh environmental conditions, including wind, rain and snow.

Heat dissipation: Aluminum has good thermal conductivity and can help dissipate heat from solar panels. This helps maintain the efficiency of solar cells, as overheating can reduce their performance.

Ocean solar uses a 30mm/35mm thick reinforced aluminum frame, which is not only light and easy to install, but also provides high-strength protection.

Post time: May-30-2024